Reinvent Your Screening Workflow with Cutting-Edge Dirt Screens for Sale

Reinvent Your Screening Workflow with Cutting-Edge Dirt Screens for Sale

Blog Article

Achieve Superior Product Separation With Advanced Dirt Screens for Recycling Plants

In the ever-evolving globe of reusing plants, accomplishing exceptional product separation is critical to making best use of performance and earnings. Enter sophisticated dirt screens, a technology that holds the pledge of reinventing the method waste is processed. These cutting edge screens are developed to successfully different dirt and other contaminants from recyclable products, ensuring a better result. However just how do they work? And what are the key benefits of integrating these displays right into recycling plant procedures? In this discussion, we will check out the solutions to these questions and dive into the variables to think about when picking dirt screens, as well as their application and maintenance. Prepare to discover the keys behind achieving premium material separation and stay tuned for the valuable understandings that exist in advance.

The Significance of Advanced Dirt Screens

The value of innovative dust displays in reusing plants can not be overemphasized as they play an essential function in separating and eliminating contaminants from recyclable products. These displays are especially made to efficiently and effectively remove dirt, debris, and other unwanted products from the reusing procedure, making certain that just tidy and high-grade recyclables are refined better.

Among the key factors why innovative dust screens are vital is that they assist improve the overall quality of recyclable products. By getting rid of impurities such as dirt, rocks, and other non-recyclable items, the displays make certain that the last recycled products are of greater pureness and fulfill the called for industry requirements. This not only improves the value of the recycled products however likewise enhances their bankability.

In addition, progressed dirt displays assist to stop damage to reusing devices. Contaminants like rocks or steel items can cause significant damages to machinery such as shredders, conveyors, and crushers, bring about expensive repair work and downtime. By properly dividing these contaminants at the beginning of the reusing process, dust screens assist to prolong the life-span of the devices and reduce upkeep expenses.

In enhancement to improving worldly quality and shielding equipment, progressed dirt screens additionally add to a more secure working environment - dirt screens for sale. By getting rid of sharp objects, harmful materials, or possibly unsafe compounds, these displays reduce the danger of injuries or mishaps to employees, ensuring a much safer office for everyone included

Just How Advanced Dirt Screens Work

Advanced dust displays in recycling plants function by using customized mechanisms to separate and get rid of impurities from recyclable materials, guaranteeing that top notch and just tidy materials continue with the reusing procedure. These displays are made to handle big volumes of blended waste and properly get rid of undesirable substances, such as dust, particles, and smaller particles, from the recyclable products.

The initial step at the same time entails the feeding of mixed waste products onto the dust screen. The screen is equipped with a series of openings or perforations that allow smaller sized particles to pass through while maintaining bigger and better materials. As the waste products move along the screen, a mix of gravitational forces and mechanical resonances aids to separate the pollutants from the recyclables.

To make the most of efficiency, advanced dirt displays utilize numerous innovations, such as oscillating or shaking screens, to enhance the separation process (dirt screens for sale). These screens can be fine-tuned to achieve the wanted separation size, guaranteeing that only the cleanest and most beneficial products continue through the reusing procedure

Additionally, some sophisticated dirt displays make use of air jets or suction systems to further boost the separation process. These systems strike or vacuum cleaner away lighter contaminants, such as paper or plastic film, leaving the heavier and much more important recyclable materials.

Trick Advantages of Using Advanced Dust Screens

Making use of innovative dirt screens in recycling my website plants offers many benefits in terms of efficiency, effectiveness, and general top quality of the reusing procedure. These sophisticated displays are made to divide dirt, debris, and various other unwanted materials from the recyclable materials, resulting in a purer end item.

One more benefit is the boosted effectiveness of the reusing process. Advanced dirt screens are designed to properly and successfully different recyclable materials from pollutants, guaranteeing a higher top quality output. This aids to fulfill rigorous recycling criteria and allows for the production of cleaner and purer products that can be utilized in different markets.

In addition to performance and efficiency, using sophisticated dirt screens likewise adds to the total quality of the reusing process. By removing dust and debris, the screens assist to reduce the more information danger of contamination, ensuring that the recycled products are of a higher criterion. This not only improves the value and marketability of the recycled materials yet additionally promotes sustainability by minimizing the demand for virgin raw products.

Factors to Take Into Consideration When Picking Dust Screens

When selecting dirt screens for recycling plants, it is crucial to take into consideration different aspects to ensure optimum performance and efficiency. Among the first variables to take into consideration is the dimension of the display. The size of the dirt screen will certainly figure out the dimension of the fragments that can pass through, so it is important to pick a screen size that is appropriate for the certain materials being refined.

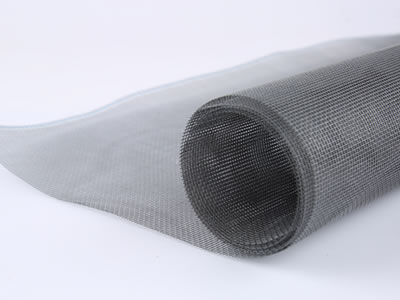

One more vital factor to think about is the product of the display. Different read review materials have various levels of sturdiness and resistance to deterioration. It is vital to select a screen material that can stand up to the harsh conditions of the recycling plant and maintain its efficiency in time.

Additionally, the design and configuration of the dirt display need to be considered. The screen needs to be designed to maximize the separation of different materials and stop clogging or obstructions. The spacing in between the wires or openings on the screen need to be very carefully picked to attain the desired splitting up performance.

Moreover, the maintenance demands of the dust display must also be taken into consideration. Screens that are simple to clean and maintain will certainly aid to decrease downtime and ensure continual procedure of the recycling plant.

Implementation and Upkeep of Dust Screens

To efficiently maintain and carry out dirt displays in recycling plants, careful consideration must be provided to their installation and ongoing maintenance. Proper installment is important to make sure the displays function ideally and offer premium material separation. During setup, it is crucial to position the screens in a manner that enables very easy gain access to for upkeep and cleansing. This might entail tactical placement of accessibility points and using appropriate assistance frameworks.

Normal maintenance is vital to maintain dust displays in optimum problem and optimize their performance. This consists of normal inspections to identify any signs of wear or damage, such as tears or holes in the displays.

Cleaning the displays regularly is also important to avoid blockages and guarantee constant procedure. This can be done utilizing different methods such as air or water blasts, depending upon the kind of screen and the degree of dust accumulation. When cleansing the displays to prevent causing any damages., it is necessary to comply with producer standards and suggestions.

Conclusion

Finally, using advanced dirt screens in recycling plants is vital for attaining superior material separation. These screens effectively remove dirt and other contaminants, guaranteeing the production of premium recycled materials. The crucial benefits of utilizing sophisticated dirt screens include increased efficiency, improved item top quality, and decreased maintenance costs. When choosing dust displays, aspects such as screen size and material should be taken into consideration. Correct application and routine maintenance of these screens are essential for optimum efficiency.

These advanced displays are developed to separate dust, debris, and various other undesirable materials from the recyclable products, resulting in a purer end product. Advanced dust displays are designed to properly and effectively separate recyclable products from contaminants, making certain a higher quality end item. The size of the dirt screen will certainly determine the dimension of the bits that can pass through, so it is crucial to pick a display dimension that is suitable for the specific materials being refined.

In conclusion, the use of advanced dust screens in recycling plants is important for accomplishing premium material splitting up. When selecting dirt screens, variables such as screen dimension and product ought to be taken into consideration.

Report this page